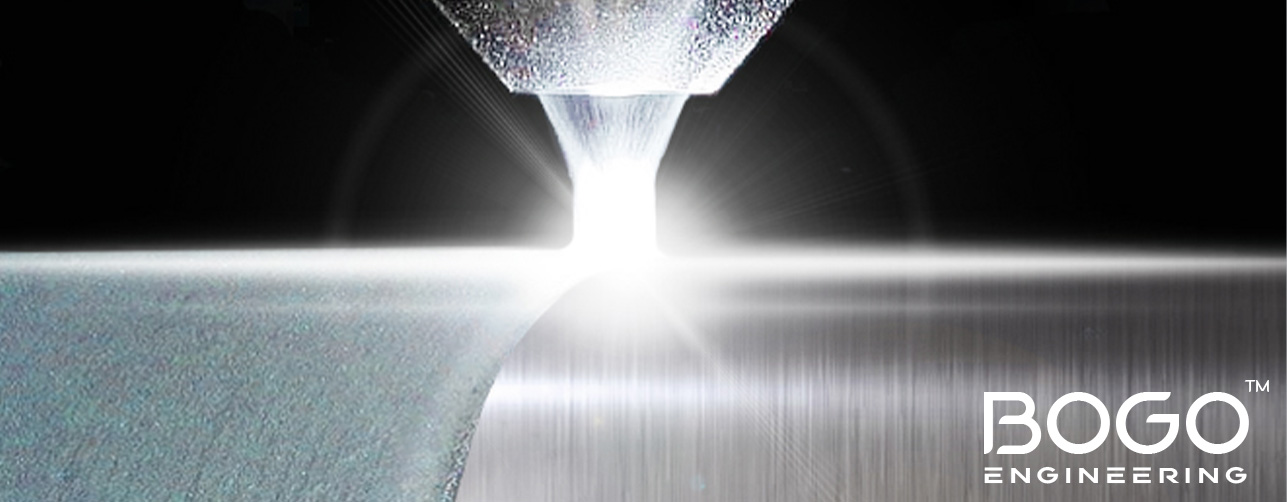

等离子焊接电极:Bogo 开发了复合钨电极,添加了如镧等添加剂,并采用独特配方确保粒度高度均匀,从而提高电极的使用寿命和性能。

等离子焊接电极

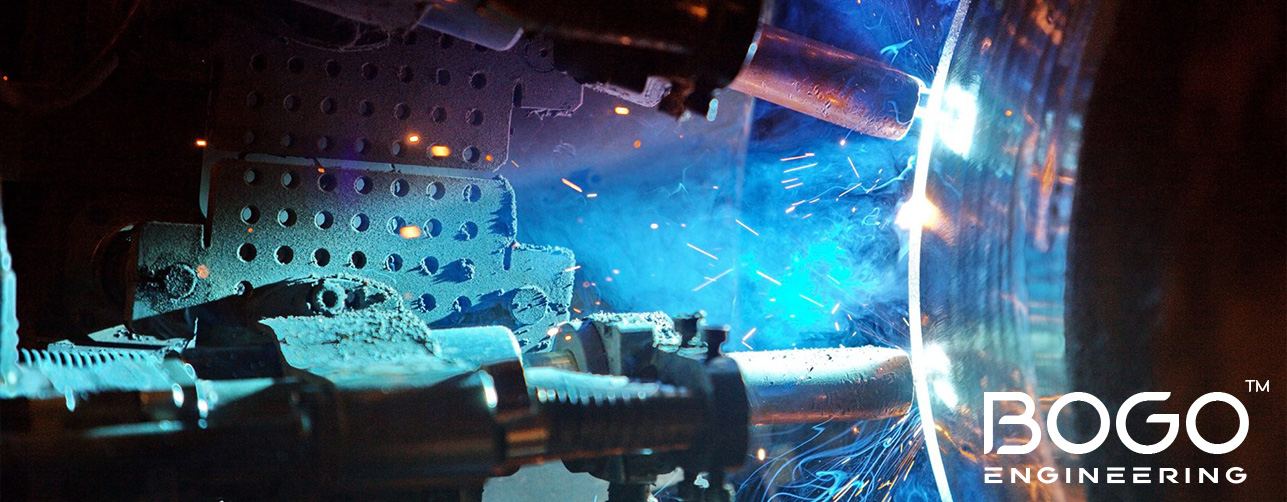

等离子焊接中使用的电极通常由钨制成,因为钨具有高熔点和良好的导电性。等离子焊接通过收缩的电弧产生高浓度的热量,可以对薄厚不一的材料进行精密焊接。

优点:

精度与控制:等离子焊接提供了极好的焊接过程控制,适合用于复杂和高精度的工作。

高质量焊缝:它能生产出高质量的焊缝,飞溅较少且边缘清晰。

多功能性:适用于焊接多种金属,包括不锈钢、铝和钛。

缺点:

成本:等离子焊接设备和电极的成本相较于其他焊接方法较高。

复杂性:设备的设置和操作需要更高的技能和培训。

维护:电极磨损相对较快,需要频繁更换以保持焊接质量。

Bogo 的突破:

增强型电极材料:开发了复合钨电极,添加了如镧等添加剂,并采用独特的配方确保粒度的高度均匀,从而提高了电极的使用寿命和性能。