纯金属、合金、复合材料和混合物高效地创建具有附加值的新表面或将组件恢复到类似新状态。

纯金属、合金、复合材料和混合物

高效地创造具有附加价值的新表面,或将部件恢复到接近新状态。

多功能应用领域

我们的材料提供解决方案,用于恢复磨损或不匹配的零件,或创造具有比基材更适合工作环境特性的表面。这些涂层材料中的许多可以单独使用,而其他一些则作为热喷涂涂层系统中的粘结涂层。一些材料作为电子产品中垫片和屏蔽应用的导电填料,而其他则作为3D金属打印的高端增材制造粉末。

常见用途

防腐蚀和抗氧化

热导率

电导率

电磁干扰(EMI)和射频干扰(RFI)屏蔽

耐磨损和抗侵蚀

恢复和修复磨损及损坏的表面和特征

作为其他热喷涂涂层的粘结涂层

增材制造

优化制造

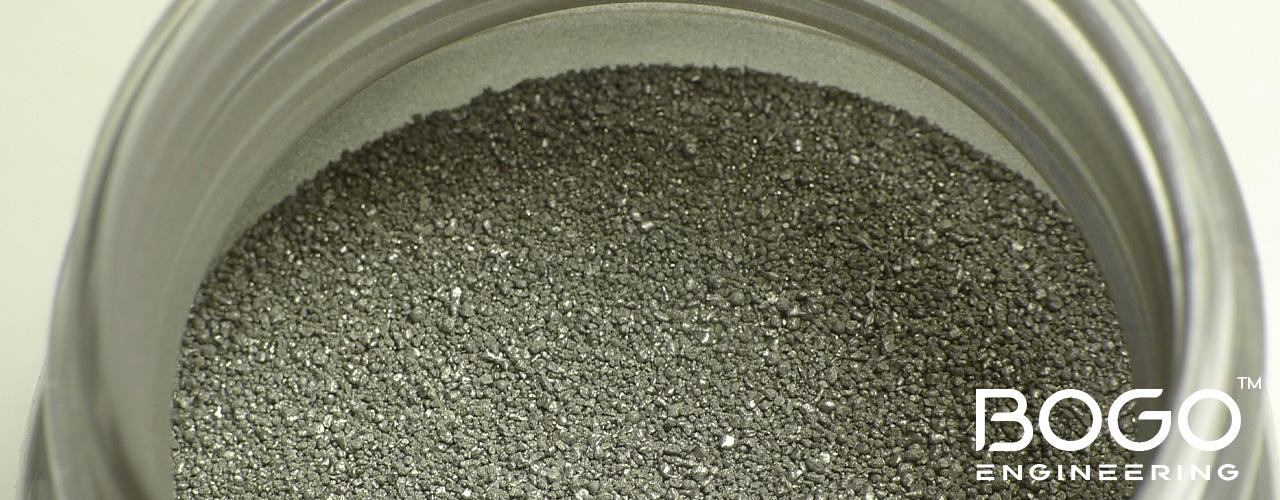

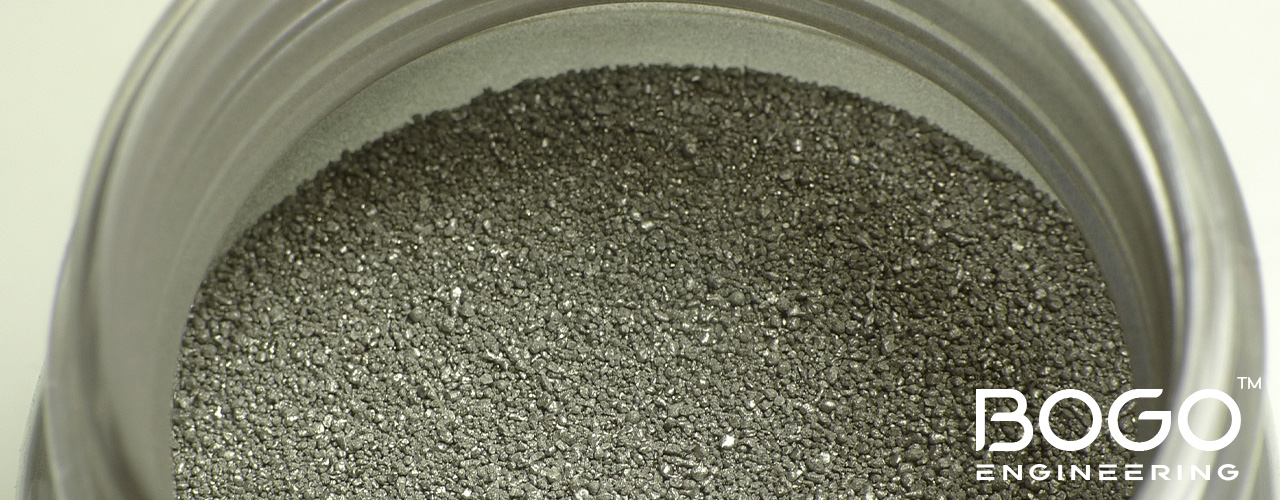

我们的产品组合基于制造专业知识和产品可靠性精心打造。我们精确控制产品化学成分和颗粒尺寸分布,以实现最佳性能,并将其量身定制以适应特定的应用工艺。通过我们在多种制造工艺中的专业能力,包括机械包覆、湿法冶金等,确保产品的一致性和高质量。

可用产品形式

粉末

工艺

产品适用于广泛的工艺:

热喷涂

高速氧气燃料喷涂(HVOF),适用于液体燃料和气体燃料

高速空气燃料喷涂(HVAF)

大气等离子喷涂

受控气氛等离子喷涂

燃烧粉末喷涂

增材制造

导电填料