MCrAlY 材料用于高温应用:为了提供优越的高温氧化和热腐蚀保护,或在具有挑战性的动态服务环境中作为结合涂层,我们推荐使用采用 MCrAlY 材料的热喷涂涂层。

MCrAlY 材料用于高温应用

为了提供卓越的高温氧化和热腐蚀保护,或者作为在严苛动态工作环境中的粘结涂层,我们推荐采用具有 MCrAlY 材料的热喷涂涂层。

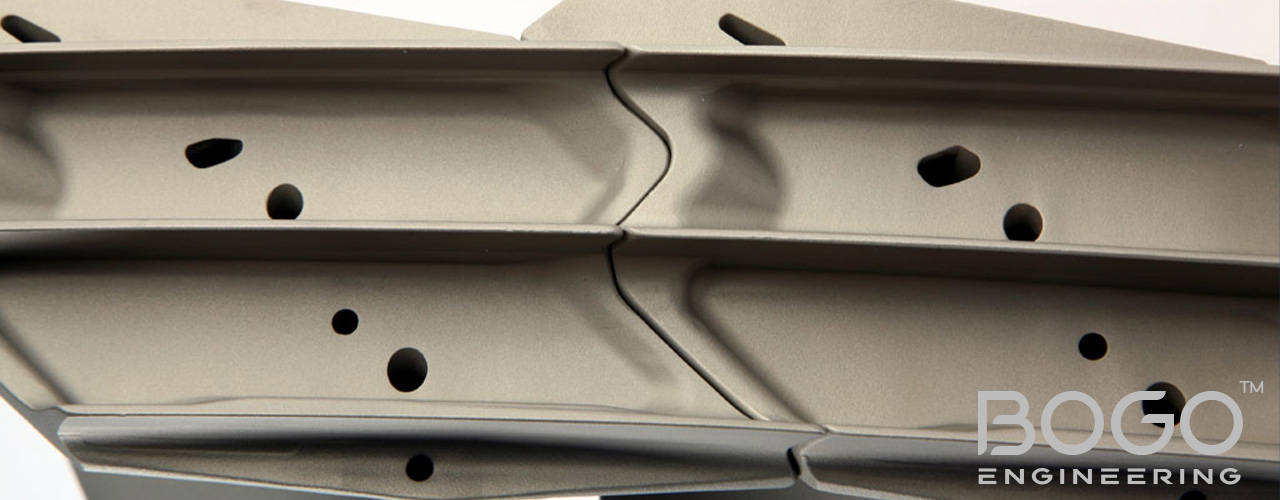

为极端工作条件设计

MCrAlY 热喷涂涂层应用于燃气涡轮发动机及其他高温腐蚀环境中最严苛的部位。它们作为有效的防腐涂层或粘结涂层,以增强热障涂层(TBC)系统和陶瓷磨损涂层系统的性能。此外,MCrAlY 材料还适用于其他高温腐蚀环境,如烟气排放管道。

MCrAlY 配方用于严苛应用

NiCrAlY 材料在高温气体环境中提供氧化保护。

CoCrAlY 化学成分表现出卓越的热腐蚀抗性,尤其是抗硫化腐蚀。

NiCoCrAlY 或 CoNiCrAlY 材料在氧化和硫化腐蚀之间达到平衡,提供两者的可接受抗性。

优化的粒度分布

我们的许多 MCrAlY 材料提供多种粒度分布,经过战略性设计,适用于不同的热喷涂工艺:

大气等离子喷涂(APS)

高速氧燃料喷涂(HVOF)

可靠的产品可靠性

我们的 MCrAlY 热喷涂涂层代表了质量和可靠性的象征,已通过认证,满足广泛的 OEM 材料规格要求。众多 OEM 依赖我们作为其独家 MCrAlY 材料制造合作伙伴,这些专有产品仅供授权的 OEM 用户使用。