适用于多种应用的氧化物陶瓷解决方案探索陶瓷涂层和材料的多功能性,提供增强的性能,如热绝缘、电绝缘,以及卓越的耐磨损和耐腐蚀性。我们的专家团队随时为您提供指导,帮助您选择理想的氧化物陶瓷解决方案,包括根据您的具体需求量身定制的完整涂层系统。

氧化物陶瓷解决方案,适用于多种应用

探索陶瓷涂层和材料的多功能性,提供如热隔离、电绝缘等增强特性,以及优越的耐磨损和耐腐蚀性能。我们的专家团队随时为您提供指导,帮助您选择理想的氧化物陶瓷解决方案,包括根据您的具体需求量身定制的完整涂层系统。

跨行业的应用证明

陶瓷材料,尤其是涂层,广泛应用于多个行业,包括:

柴油发动机活塞

汽车阀门和气缸

飞机和工业燃气轮机部件的热障涂层

涡轮发动机热端部件的高温可磨损涂层

固体氧化物燃料电池(SOFC)部件

印刷行业的安尼洛克辊和电晕辊

造纸行业的辊筒和医生刮刀

具有气体渗透能力的氧气传感器

用于物理气相沉积(PVD)涂层的溅射靶材

纺织制造的纤维和导丝

生物医学植入物

纤维制造辊筒

用于保护半导体制造腔体免受等离子刻蚀的涂层

金属铸造槽、液压缸和机械密封等工业应用

广泛的标准粉末化学成分范围

凭借我们全面的库存和全球供应,您可以享受到各种基础化学成分的陶瓷粉末,包括:

稳定化铝土矿(YSZ)

氧化铝

铬土矿

钛土矿

钇土矿

镧锶锰(LSM)

结合型和稀土元素的特殊化学成分

针对多种工艺的优化产品

我们的氧化物陶瓷粉末经过精心设计,适用于特定工艺,包括:

大气喷涂(APS)

燃烧粉末热喷涂

等离子喷涂-物理气相沉积(PS-PVD)

陶瓷注射成型(CIM)

我们还提供悬浮等离子喷涂的产品,提供预混粉末溶液和干粉,方便与您的悬浮液体混合。

量身定制的热障涂层(TBC)材料

从一系列TBC材料中选择,每种材料都经过战略性制造,适用于特定应用:

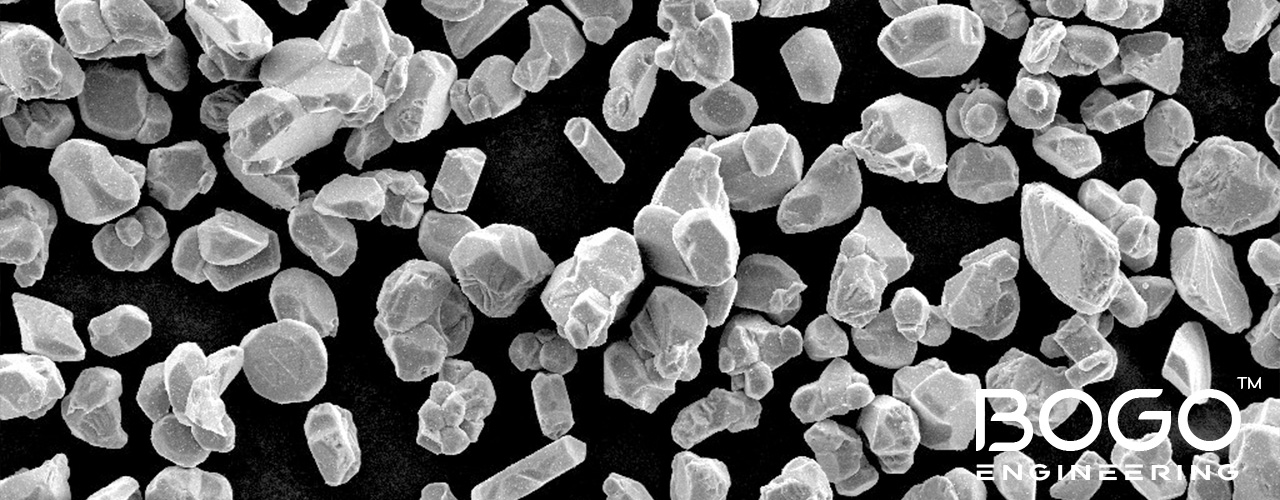

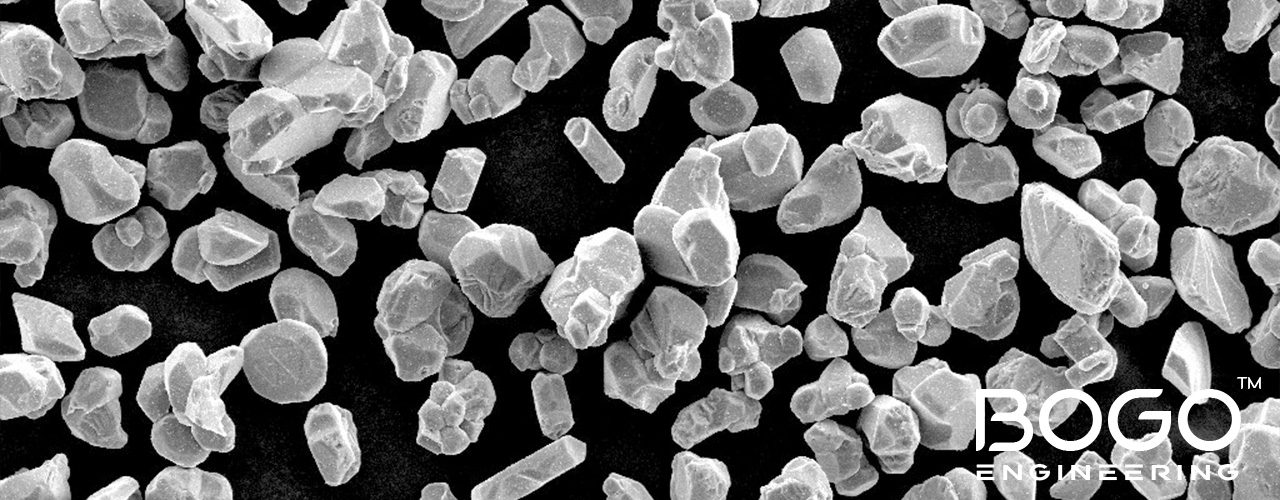

聚集和致密化的球形粉末——适用于标准孔隙度和高沉积效率应用

聚集和烧结的粉末——适用于高孔隙度和厚TBC涂层

熔融和破碎的粉末——推荐用于低孔隙度TBC涂层,具有增强的耐蚀性

涂层应用的全面解决方案

由于热喷涂氧化物陶瓷涂层需要一个粘结涂层以确保良好附着力,您可以利用我们丰富的合金和MCrAlY材料产品组合。让我们的专家为您推荐量身定制的理想粘结涂层材料,以满足您的具体需求。

除了提供合适的材料外,我们还与您合作,采用先进、高效的涂层应用技术,确保最佳的涂层结构和加工效率。

创新与定制解决方案

凭借强大的研发能力,我们专注于为最具挑战性的操作条件开发新的氧化物陶瓷配方和涂层,包括复杂和特殊的配方。信任我们,满足您的所有陶瓷涂层需求。