SG-100 阳极:Bogo 独有的 DBC 无缝结合技术显著提升产品性能,使接触面积、电阻和散热更加均匀,从而延长产品使用寿命。

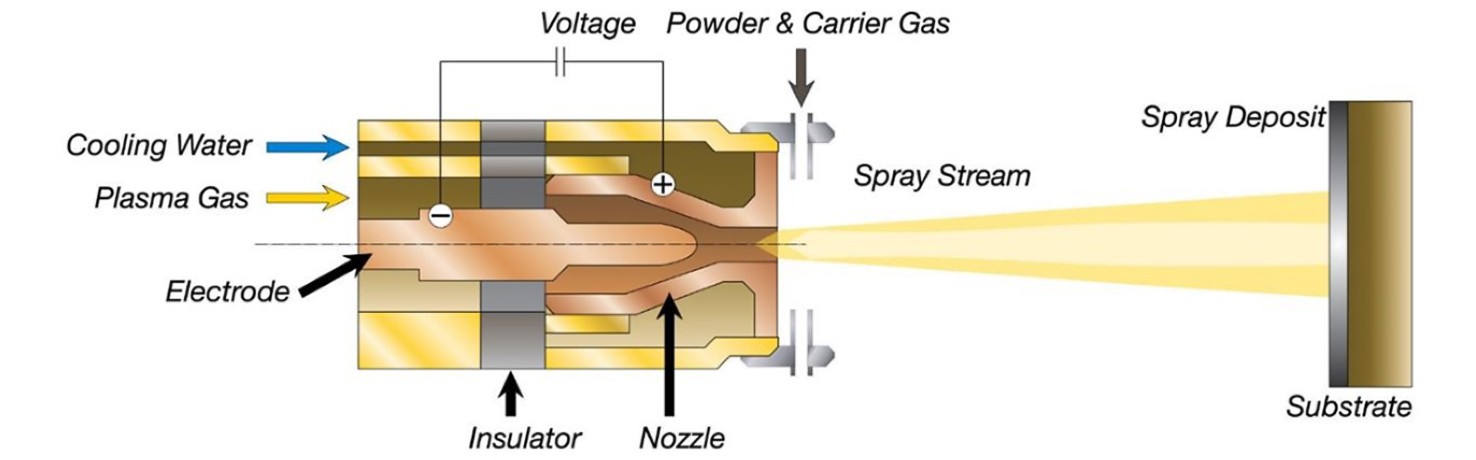

欢迎来到我们尖端的等离子喷涂世界,这是一种现代工业生产中最广泛应用且最具多功能性的热喷涂工艺。通过在金属、陶瓷和聚合物等基材上涂覆各种功能层,等离子喷涂技术可确保涂层具有卓越的结合强度、出色的性能、长久的使用寿命、高可靠性以及最小的基材变形。

在我们公司,我们专注于生产铜钨电极(亦称阴极和阳极),并采用精密的等离子喷涂技术。我们的电极喷嘴采用优质钨电极,具备卓越的电弧点火性能和超长使用寿命。钨与铜之间的无缝结合技术确保了工艺的稳定性。我们成熟且全面的产品线广泛兼容Metco、GTV、FST、Praxair、Thermach、Progressive Surface等知名公司的喷枪,包括F4、F1、9M、SG-100、MP-200等型号。

我们的喷涂铜钨电极的关键技术优势:

采用卓越的新型高性能钨电极,确保出色的电弧点火性能和抗侵蚀能力,并可提供多种掺杂稀土元素的钨电极选项。

钨与铜的无缝结合,相较于传统钎焊,具备更高的结合强度,大幅提升产品性能,确保均匀的接触面积、电阻和散热效果,从而延长产品使用寿命。

提供多种类型的阴极和阳极产品,产品线丰富且多样化。

拥有丰富的定制加工经验,可根据客户提供的样品或图纸进行生产。

积极响应客户需求,不断优化喷嘴设计,以延长其使用寿命。

可提供钨铜无缝结合的半成品,以满足不同应用需求。

面对工业生产对材料日益增长的需求,我们公司专注于采用等离子喷涂技术,提供先进的铜钨电极。我们的电极和喷嘴由高质量钨材料制成,并经过致密化处理,确保快速电弧启动、稳定电压及缓慢衰减,性能优于同类原厂产品。

我们独特的 DBC(扩散结合铸造)技术,实现了铜与钨的无缝结合,确保优异的散热能力,并增强钨铜电极的抗烧蚀能力和耐久性。