Regulators and consumers are increasingly seeking environmentally friendly mobility solutions while also emphasizing heightened robustness and safety standards for vehicle operators and passengers.

In the dynamic landscape of the automotive industry, characterized by globalization, competition, and price pressures, Bogo Engineering offers cutting-edge coating solutions for diverse components. Our aim is to enhance vehicle operational efficiency and minimize environmental impact in crucial areas such as:

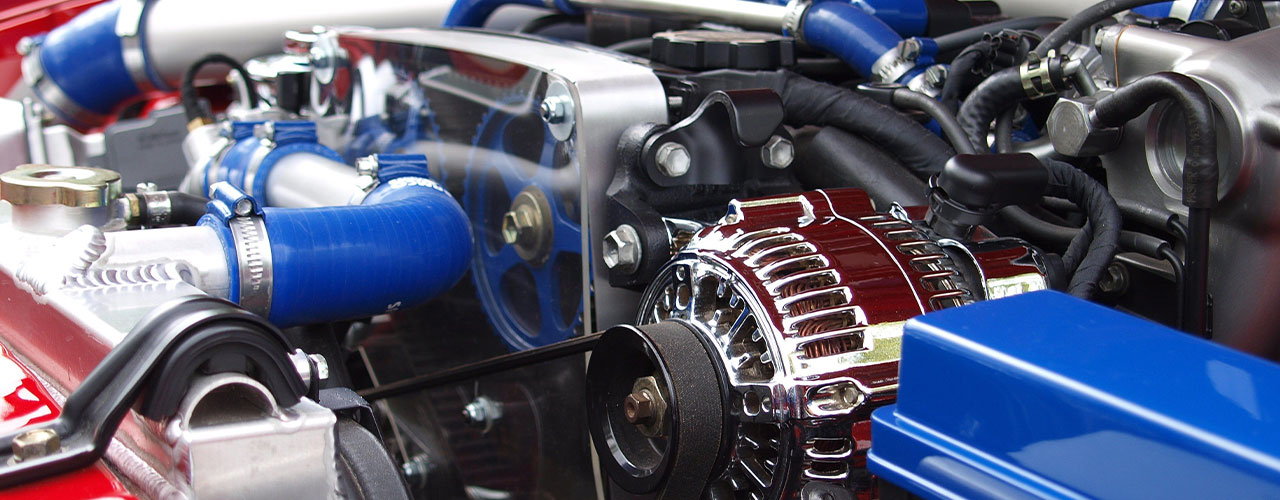

Engine systems

Brake systems

Steering and suspension

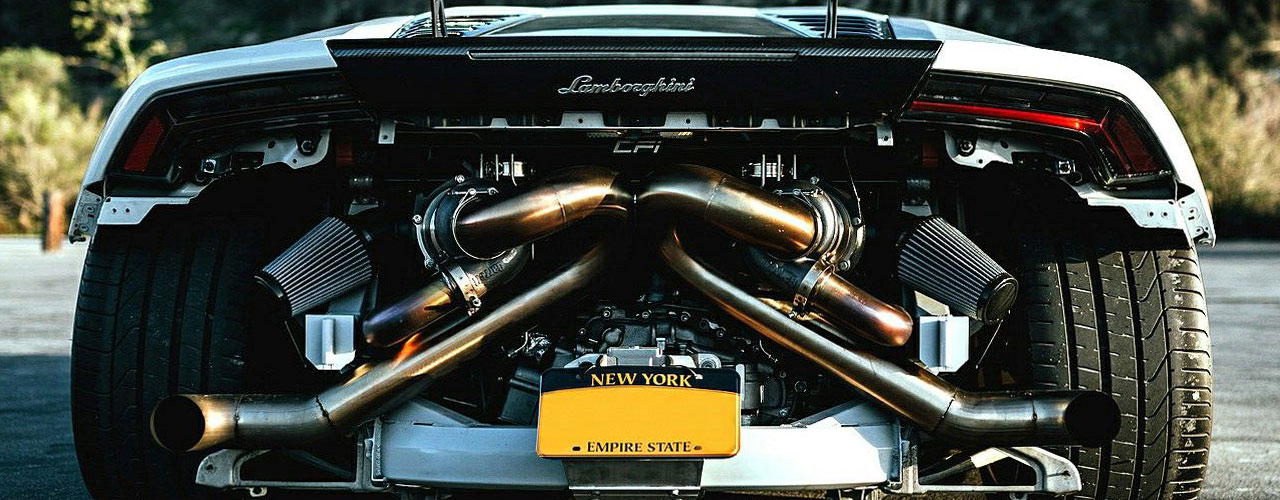

Exhaust gas treatment

Our specialized solutions, rooted in innovative materials and advanced coatings, empower you to outpace the competition by:

Reducing weight, leading to heightened efficiency and decreased fuel consumption in internal combustion engines

Extending the service life of essential components through minimized corrosion, friction, and wear

Streamlining production processes for greater efficiency and flexibility

Introducing innovative design solutions

As your comprehensive provider, Bogo Engineering delivers:

Materials

Integrated Systems

Coating Services

Equipment

Dedicated Customer Support

Elevated combustion temperatures, driven by the pursuit of greater efficiency, result in higher exhaust gas temperatures. These elevated temperatures can have adverse effects on the functionality and lifespan of NOx and oxygen sensors situated in the exhaust pipe and catalyst.

Our gas-permeable ceramic coatings shield your sensors from hot gas corrosion, guaranteeing a dependable closed-loop emission control system for your engine.

Experience an extended service life for your NOx and oxygen sensors

Achieve consistent emission control through enhanced long-term sensor reliability.

Effective thermal management is paramount for electric vehicles, spanning rapid and efficient cabin heating to pre-heating sensitive electronic components in cold conditions.

Our cutting-edge multi-layer coatings revolutionize the creation of compact and lightweight electric heaters, leading to reduced packaging size, quicker installation, and lower energy consumption.

Revolutionizing Brake Discs

In hybrid and electric vehicles, where recuperation handles braking functions, mechanical brakes see less use, leading to potential disc corrosion and a subsequent risk of reduced braking power—especially critical in emergencies.

Combustion engines serve as the beating heart of various vehicles, from passenger cars and commercial trucks to motorcycles and motorsports cars. Their influence extends to maritime vessels, stationary power plants, aero engines, as well as leisure vehicles like snowmobiles, lawnmowers and chainsaws.

Addressing the formidable challenge of meeting stringent emission regulations remains a top priority for manufacturers across the automotive spectrum.

Enhance fuel economy through low-friction coatings and lighter engines.

Augment corrosion and wear resistance.

Slash oil consumption by up to 82%.

Our rub-tolerant coatings optimize clearance management between the housing and wheel, boosting turbocharger efficiency. Acting as a buffer, these coatings mitigate wheel and housing incursions resulting from eccentric rotational conditions, ensuring prolonged service life.

Additionally, thermal barrier coatings on the turbine housing effectively reduce thermal radiation from the turbocharger, facilitating a more space-efficient enghine layout.

Experience up to 3% Higher Efficiency

Our rub-tolerant coatings have demonstrated remarkable results in gap control, with one Bogo customer achieving up to 3% higher efficiency.

Enhanced Engine Layout Flexibility

The incorporation of thermal barrier coatings provides greater flexibility in designing engine layouts, enabling more adaptable and efficient arrangements.