MCrAlY Materials for Elevated Temperature Applications: For superior protection against high-temperature oxidation and hot corrosion, or as a bond coat in challenging dynamic service environments, our recommendation lies with thermal spray coatings featuring our MCrAlY materials.

For superior protection against high-temperature oxidation and hot corrosion, or as a bond coat in challenging dynamic service environments, our recommendation lies with thermal spray coatings featuring our MCrAlY materials.

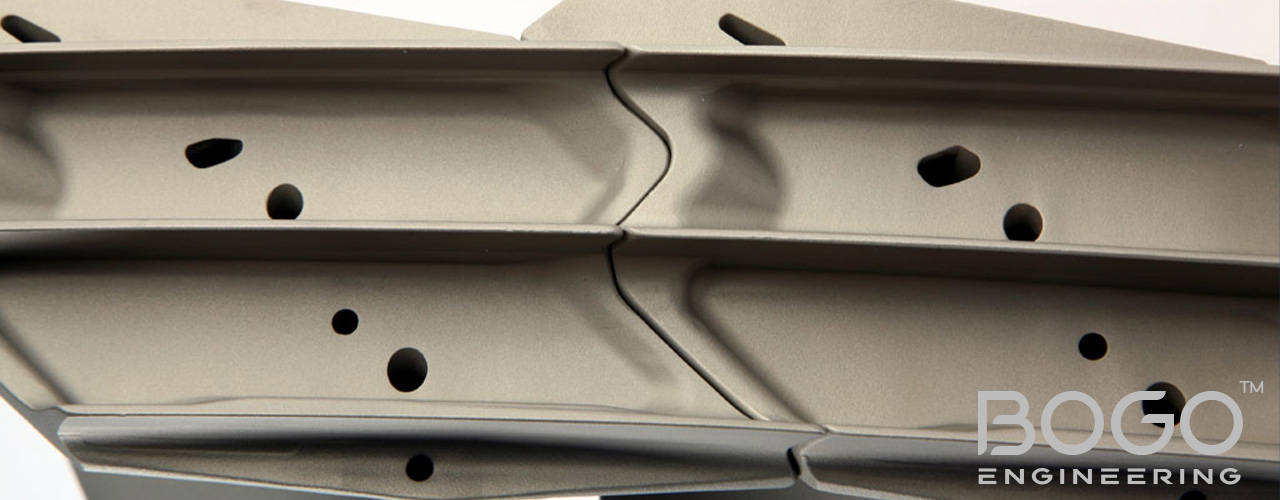

MCrAlY thermal sprayed coatings find application in the most demanding sections of gas turbine engines and other high-temperature, corrosive environments. They serve as effective anti-corrosion coatings or bond coats to enhance the performance of Thermal Barrier Coating (TBC) systems and ceramic abradable coating systems. Furthermore, MCrAlY materials are suitable for deployment in other high-temperature, corrosive settings such as flue gas stacks.

NiCrAlY materials provide oxidation protection in high-temperature gas environments.

CoCrAlY chemistries exhibit exceptional resistance to hot corrosion, specifically sulfidation.

NiCoCrAlY or CoNiCrAlY materials strike a balance, offering acceptable resistance to both oxidation and sulfidation.

Many of our MCrAlY materials are available with various particle size distributions, strategically designed for suitability across different thermal spray processes:

Atmospheric plasma spray

High Velocity Oxygen Fuel (HVOF)

Our MCrAlY thermal spray coatings stand as a testament to quality and reliability, certified to meet a broad spectrum of OEM material specifications. Numerous OEMs rely on us as their exclusive MCrAlY material manufacturing partner, with these proprietary products exclusively accessible to authorized OEM users.