Cermet Materials for Enhanced Coating Performance: Cermets, composed of ceramic and metal materials, serve as crucial intermediate layers in multi-layer metallic-ceramic coating systems. These materials effectively address thermal expansion mismatches, providing an optimal solution to enhance coating performance and extend the life of applications subjected to severe thermal cycling.

Cermets, composed of ceramic and metal materials, serve as crucial intermediate layers in multi-layer metallic-ceramic coating systems. These materials effectively address thermal expansion mismatches, providing an optimal solution to enhance coating performance and extend the life of applications subjected to severe thermal cycling.

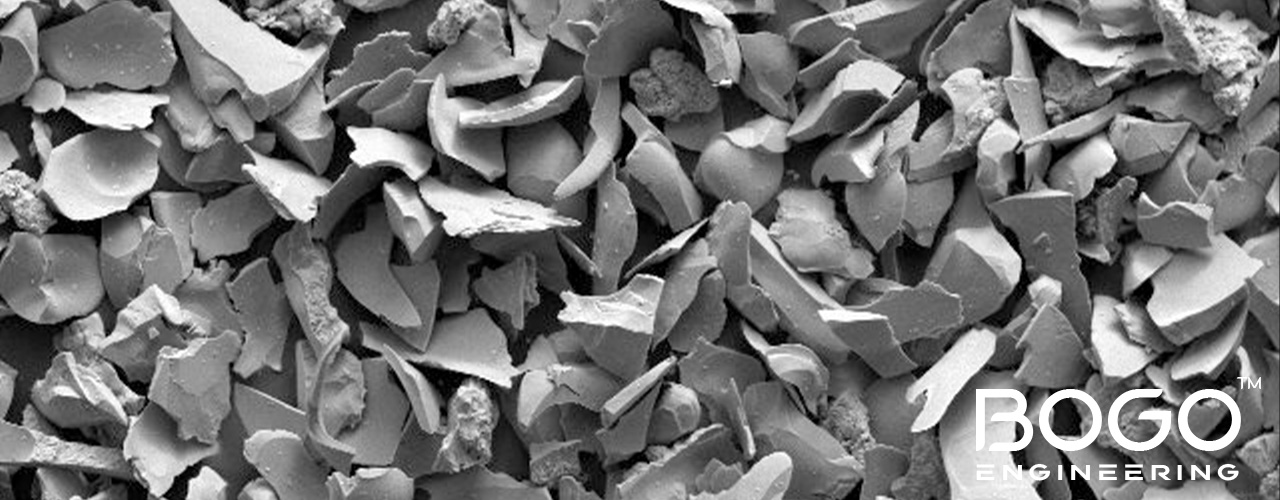

A "cermet" is a composite of metal-oxide ceramic (cer) and metal (met) materials. It manages thermal expansion differences between the substrate and the functional coating by serving as an intermediate layer between the metallic bond coat and the ceramic top coat. Initially designed for turbine applications, such as thermal barriers and clearance control coatings, cermets prove valuable in diverse applications where intense thermal cycling could lead to premature failure in a simple two-layer coating system.

Common Applications of Cermets Include:

Cutting Tools: Cermet is widely utilized in the manufacturing of cutting tools like drill bits, saw blades, and milling cutters due to its high hardness and wear resistance, making it ideal for cutting hard materials such as metal, wood, and plastic.

Wear-Resistant Coatings: Used as a coating material to enhance wear resistance in surfaces like engine components, turbine blades, and industrial equipment, cermet's corrosion and erosion resistance make it suitable for protecting critical components in challenging environments.

Aerospace Applications: Employed in the aerospace industry for its high strength-to-weight ratio, resistance to high temperatures, and corrosion resistance, cermet finds use in manufacturing engine components, heat shields, and other vital aerospace parts.

Electronics: Utilized in the electronics industry for its thermal conductivity and resistance to oxidation, cermet is used in the manufacturing of resistors and other electronic components.

We offer a range of metal/ceramic powder blends designed for use with:

Alumina- and zirconia-based top coat powders

Nickel-, aluminum-, and chromium-based bond coat powders

Additionally, we provide both bond and top coat powder products, along with cutting-edge thermal spray equipment, enabling you to acquire the complete coating system from a single, high-quality source.