Abradable Coating for Enhanced Turbo machinery Efficiency: Our abradable materials revolutionize safety, cut fuel consumption, and minimize emissions in various turbo machinery applications, including aviation and power generation gas turbines, steam turbines and turbochargers.

Our abradable materials revolutionize safety, cut fuel consumption, and minimize emissions in various turbomachinery applications, including aviation and power generation gas turbines, steam turbines and turbochargers.

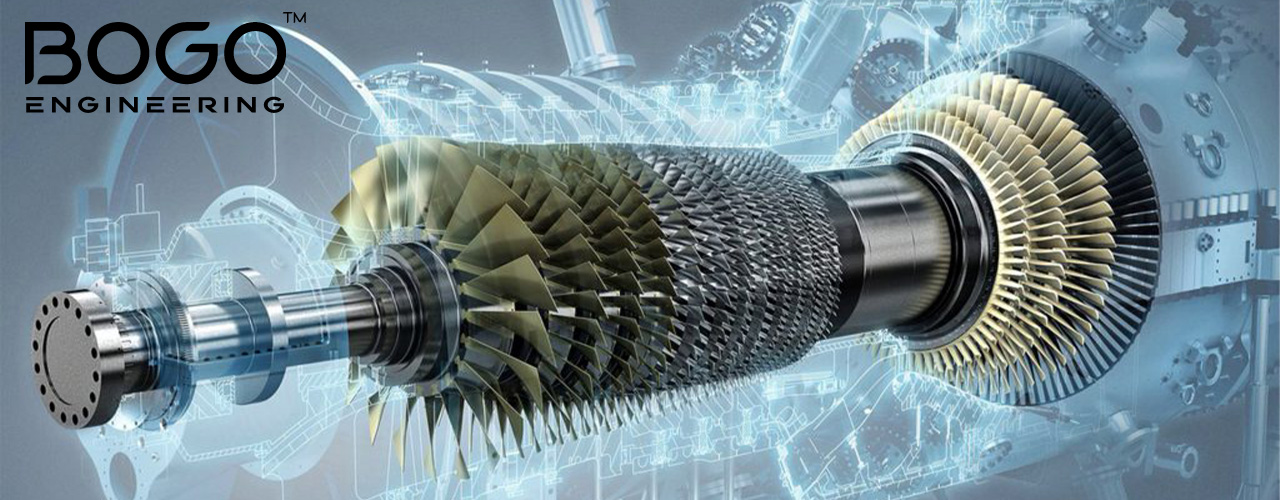

The term "abradable" describes materials or coatings designed to gradually wear away through contact with another surface. This technology significantly reduces friction, minimizing damage to critical surfaces. Abradable materials find extensive use in rotating machinery, such as gas turbines, where they serve as coatings or inserts in the casing surrounding turbine blades.

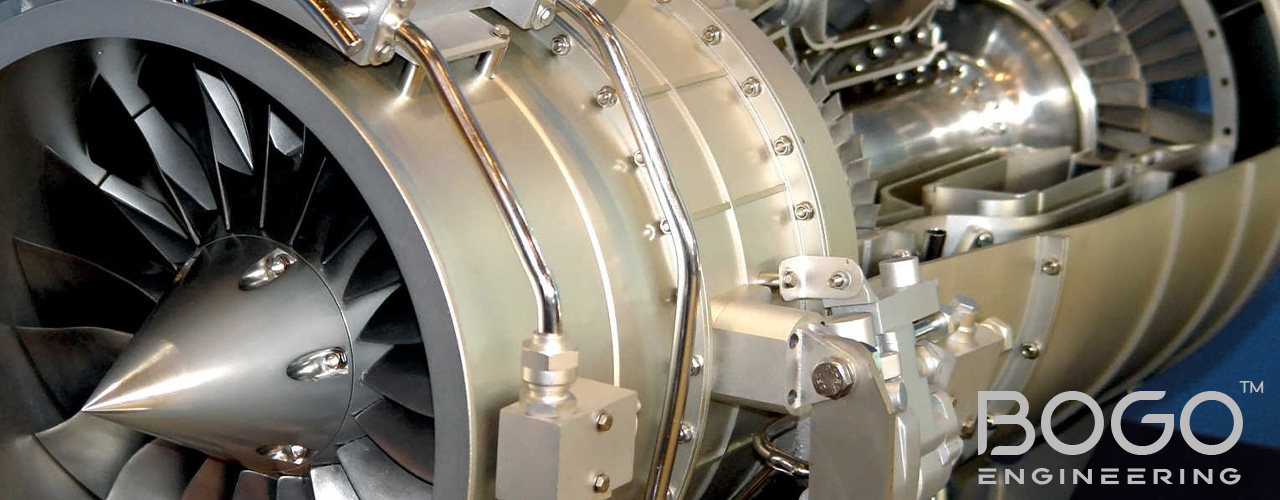

In high-speed rotating machinery like gas turbines, our abradable coatings create a controlled clearance between the blade tips and casing. This minimizes rubbing, friction, wear, vibration, and noise, while enhancing efficiency and overall performance.

We design and produce high-quality abradable coatings for various critical turbomachinery applications.

Our composite abradable thermal spray powders guarantee long-lasting service, and we employ an in-house testing rig to simulate engine conditions. This allows us to rapidly and confidently qualify abradable solutions under diverse conditions.

High quality abrdable solutions significantly enhance the efficiency and safety of aircraft propulsion engines, logging millions of flight hours annually in both civil and military turbofan, turboprop, and turboshaft engines.

Applications include:

Rotor path linings,

Compressor seals,

Turbine seals,

Bearing air seals,

Oil seals

Labyrinth seal configurations.

Operational Benefits include:

Reduces Specific Fuel Consumption

Increases compressor stall margins

Lowers engine Exhause Gas Temperatures, extending the engine on-wing time

In industrial gas turbine compressors, high quality abradable coatings improve efficiency by up to 5%. Additionally, ceramic abradable materials applied to shroud seal segments in the turbine section enhance stage efficiency by up to 2%.

Operational benefits include:

Increased power output

Reduced fuel consumption

Lower greenhouse gas emissions

Significantly reduced operating costs

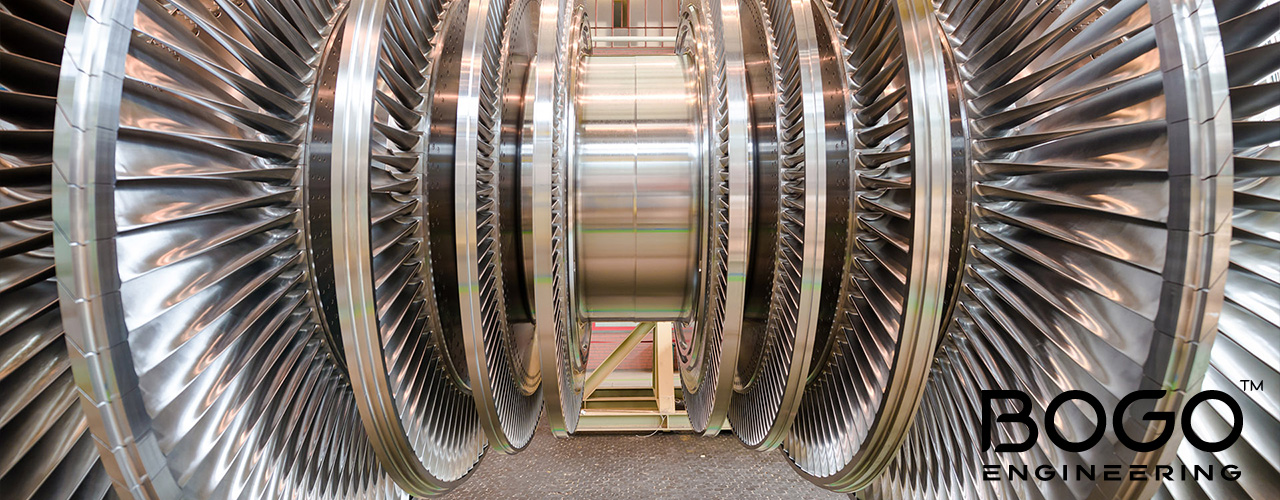

High quality abradable solutions for steam turbines,

Typically applied to:

Shaft seals

Balance piston seals

Steam flow path seals

Operational benefits include:

Enhance efficiency

Reduce carbon dioxide emissions

Save fuel

Decrease environmental costs

Explore the possibilities of abradable coatings with Bogo Engineering for a future of enhanced efficiency and reduced environmental impact.