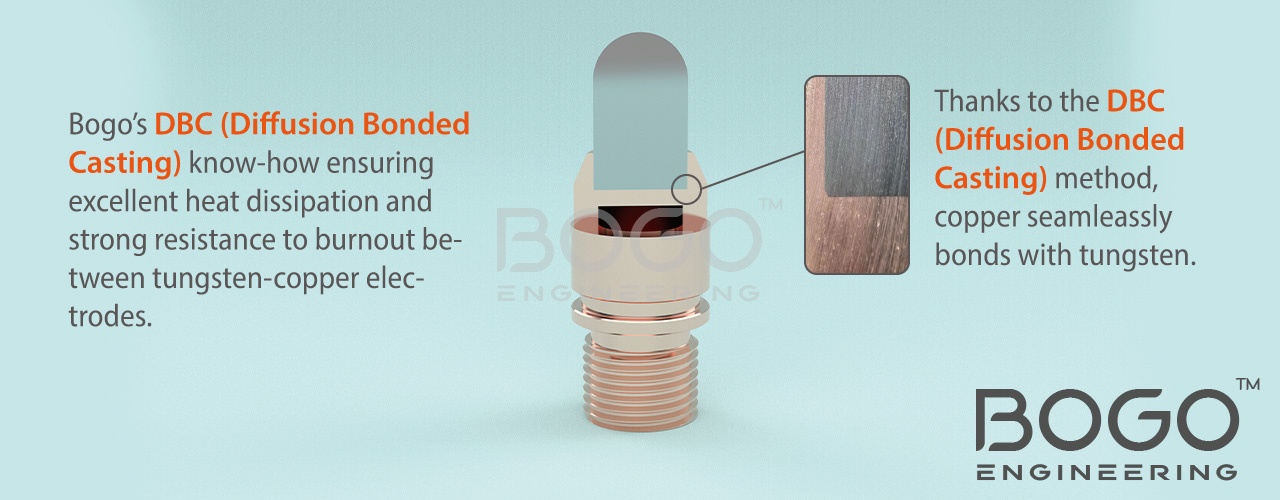

MP-200 Cathode: Bogo's DBC exclusive know-how seamless bonding technology enhances product performance significantly, as the contact area, resistance, and heat dissipation are more uniform, ensuring a prolonged product lifespan.

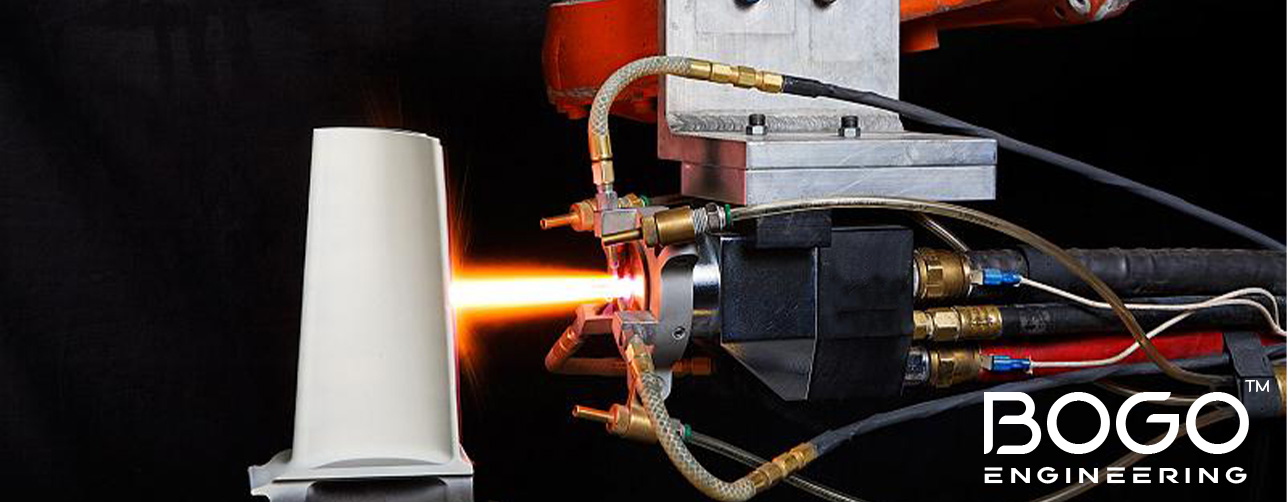

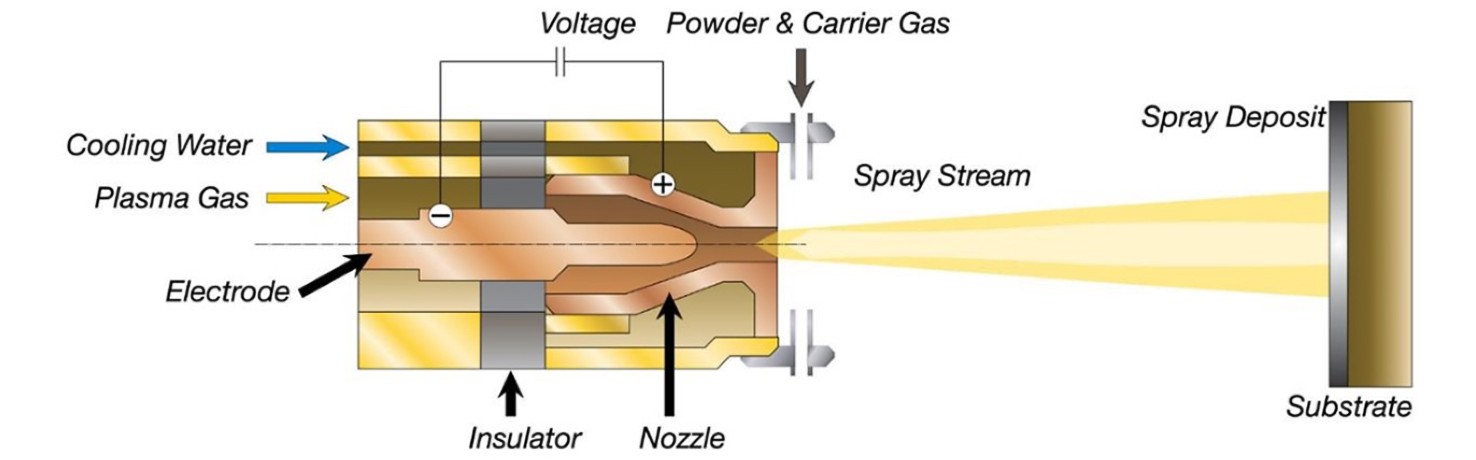

Welcome to our cutting-edge world of Plasma Spraying, the most widely used and versatile thermal spraying process in modern industrial production. With the ability to coat various functional layers on substrates like metals, ceramics, and polymers, plasma spraying technology ensures coatings with outstanding bonding strength, exceptional performance, long service life, high reliability, and minimal substrate deformation.

At our company, we excel in the production of copper-tungsten electrodes, also known as cathodes and anodes, utilizing the precision of plasma spraying technology. Our electrode nozzles boast top-quality tungsten electrodes, delivering exceptional arc ignition performance and longevity. The seamless bonding technology between tungsten and copper ensures the stability of your processes. Our comprehensive and mature product line is widely compatible with spray guns from renowned companies like Metco, GTV, FST, Praxair, Thermach, Progressive Surface, including models such as F4, 9M, SG-100, MP-200 and more.

Key Technical Advantages of our Spray-Coated Copper-Tungsten Electrodes:

Utilization of high-performance tungsten electrodes in unrivaled new materials, ensuring excellent arc ignition performance and erosion resistance. Various rare-earth-doped tungsten electrode options are available.

Seamless bonding of tungsten and copper, resulting in higher bonding strength compared to traditional brazing. This significantly enhances product performance, ensuring uniform contact area, resistance, and heat dissipation, leading to a prolonged product lifespan.

Diverse types of cathode and anode products, offering a rich and versatile product line.

Extensive experience in custom processing, accepting customer samples or drawings for production.

Responsive to customer needs, making continuous improvements to nozzles to enhance their lifespan.

Pleased to provide semi-finished products with seamless tungsten-copper bonding.

In response to the increasing demand for materials in industrial production, our company specializes in providing advanced Copper-Tungsten electrodes using Plasma Spray Technology. Our electrodes and nozzles, crafted from high-quality tungsten material and treated for densification, ensure rapid arc initiation, stable voltage, and slow degradation—outperforming similar original products.

Combining our unique DBC (Diffusion Bonded Casting) know-how seamlessly bonds copper with tungsten, ensuring excellent heat dissipation and strong resistance to burnout between tungsten-copper electrodes. For more details, please refer to our product manual: Plasma Spray Electrodes and Nozzles.

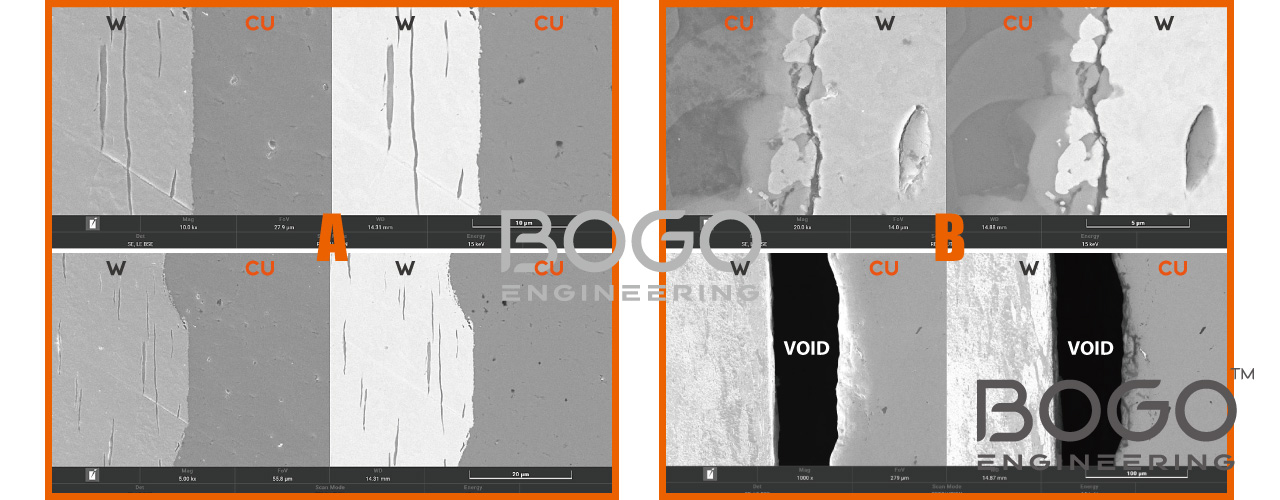

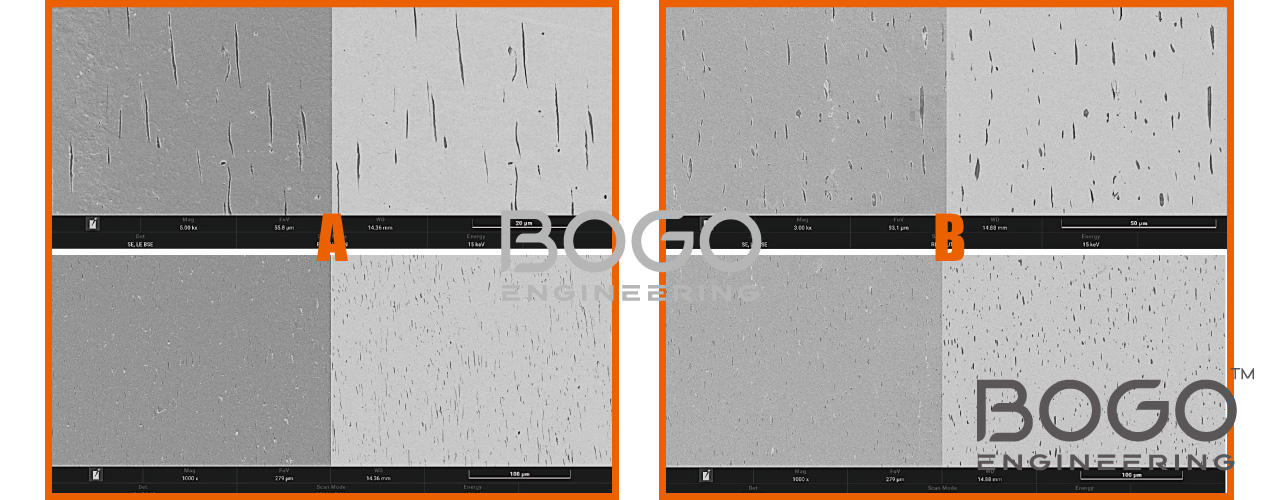

Bogo's DBC (Diffusion Bonded Casting) know-how seamlessly bonds copper with tungsten (A) when compare to brazing method (B).

Bogo's unique compacting technology for tungsten electrodes creates a refined and uniform crystal structure (A) when compared to conventional products (B). This results in higher hardness and density, leading to quick arc initiation, minimal wear, and an extended lifespan.

Technical Advantages of our Spray-Coated Copper-Tungsten Electrodes:

Utilization of high-quality tungsten alloy, offering easy arc initiation, stability, and minimal erosion, resulting in a longer cathode lifespan.

| Material | Oxide Doped(wt.%) | Tungsten(wt.%) | Additive(wt.%) | Emission(eV) |

| Pure Tungsten | - | 99.95 | - | 4.25 - 5.01 |

| Lanthanum Tungsten | 1% | Balance | 1-2% (Choosable) | 1.7 - 4.2 |

| Thorium Tungsten | 2% | Balance | 1-2% (Choosable) | 2.0 - 3.0 |

| Cerium Tungsten | 2% | Balance | 1-2% (Choosable) | 2.0 - 3.9 |

Adoption of the unique BOGO's DBC bonding technology, ensuring outstanding thermal conductivity and balanced performance. The cross-sectional diagrams of our raw materials and processed products using DBC technology demonstrate a seamless fusion of tungsten and copper. The DBC method removes voids between copper and tungsten, enhancing heat conductivity. With copper's excellent thermal conductivity, all our thermal spray electrodes boast a prolonged lifespan.